FCM Approval with Complete Documentation

As we process and sell food-approved materials, we are, in accordance with applicable legislation, registered with and inspected by the Danish Veterinary and Food Administration.

You can find our latest inspection reports from the food authority’s smiley scheme here.

You can read more about the definition here.

Since January 2016, all declarations of conformity for plastics intended for food contact must comply with EU directive EU10/2011, Annex IV, and be based on documentation in accordance with EU10/2011, Article 18.

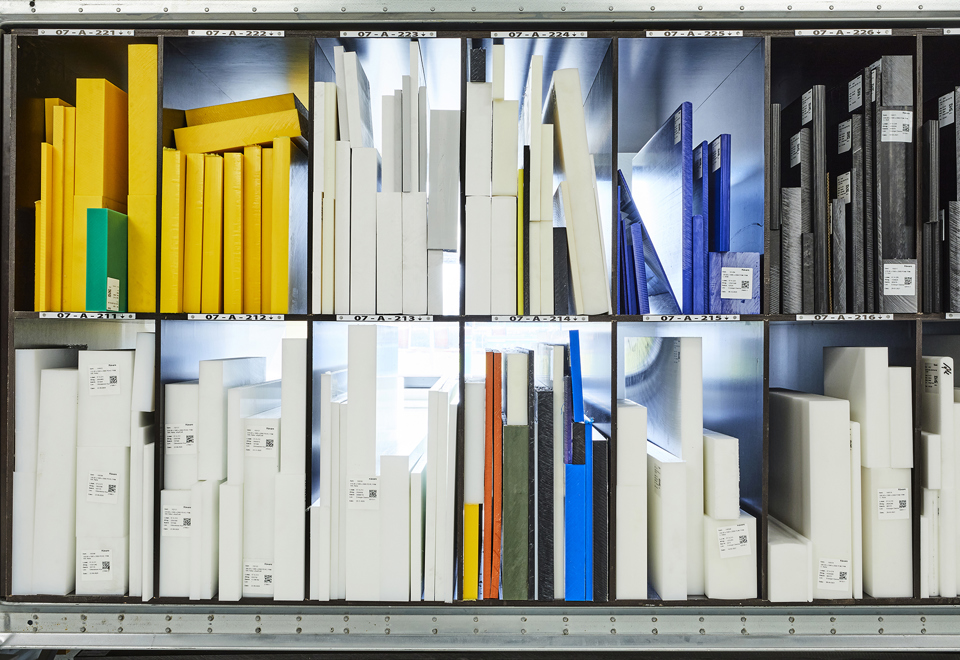

All relevant documentation regarding the materials related to EU directive EU10/2011 can be found in our plastic range. This ensures clarity about the material's application and capabilities—and, of course, complete traceability.

Additionally, our FKM plastic range includes the relevant migration tests, allowing you to easily and quickly determine whether the material has been tested according to your requirements. These tests are conducted in the laboratory of our raw material producer.

UL94

For the classification of the flammability of plastic materials, Underwriters Laboratories in the USA has developed the standard UL94.

Our raw materials are all tested and classified according to UL94. These tests are conducted in the laboratory of the raw material producer.

Upon order placement, we are happy to provide documentation for testing and standard compliance upon request.

The standard classifies materials based on their flammability into six groups, from lowest to highest (most flame-retardant) level:

| Classification | Description |

| HB | Slow burning rate / flame continues |

| V2 | Flame extinguishes within 30 seconds. Dripping burning molten plastic is acceptable. |

| V1 | Flame extinguishes within 30 seconds. Dripping molten plastic is acceptable, but must not burn. |

| V0 | Flame extinguishes within 10 seconds. Dripping molten plastic is not acceptable, but melting of the material is allowed. |

| 5VB | Flame extinguishes within 60 seconds. Dripping molten plastic is not acceptable, but melting of the material is allowed. |

| 5VA | Flame extinguishes within 60 seconds. Dripping molten plastic and melting of the material are not acceptable. |

Have any questions?

Bárður Jónsson Stórá

Sales Coordinator

Tina Heslop Christensen

Sales and Project Coordinator