QUPAQ is one of the world's leading manufacturers of automated solutions for food packaging. For their machines, the company has partnered with Induflex, which has been producing and supplying machine parts in food-grade plastic for over a decade.

One of QUPAQ's innovative solutions is INTRAY, a tray dispenser created with a focus on meeting the needs of food companies globally. INTRAY represents a hygienic, fast, and secure method for dispensing trays for items such as meat, poultry, fruits, vegetables, and snacks.

Induflex Machine Parts

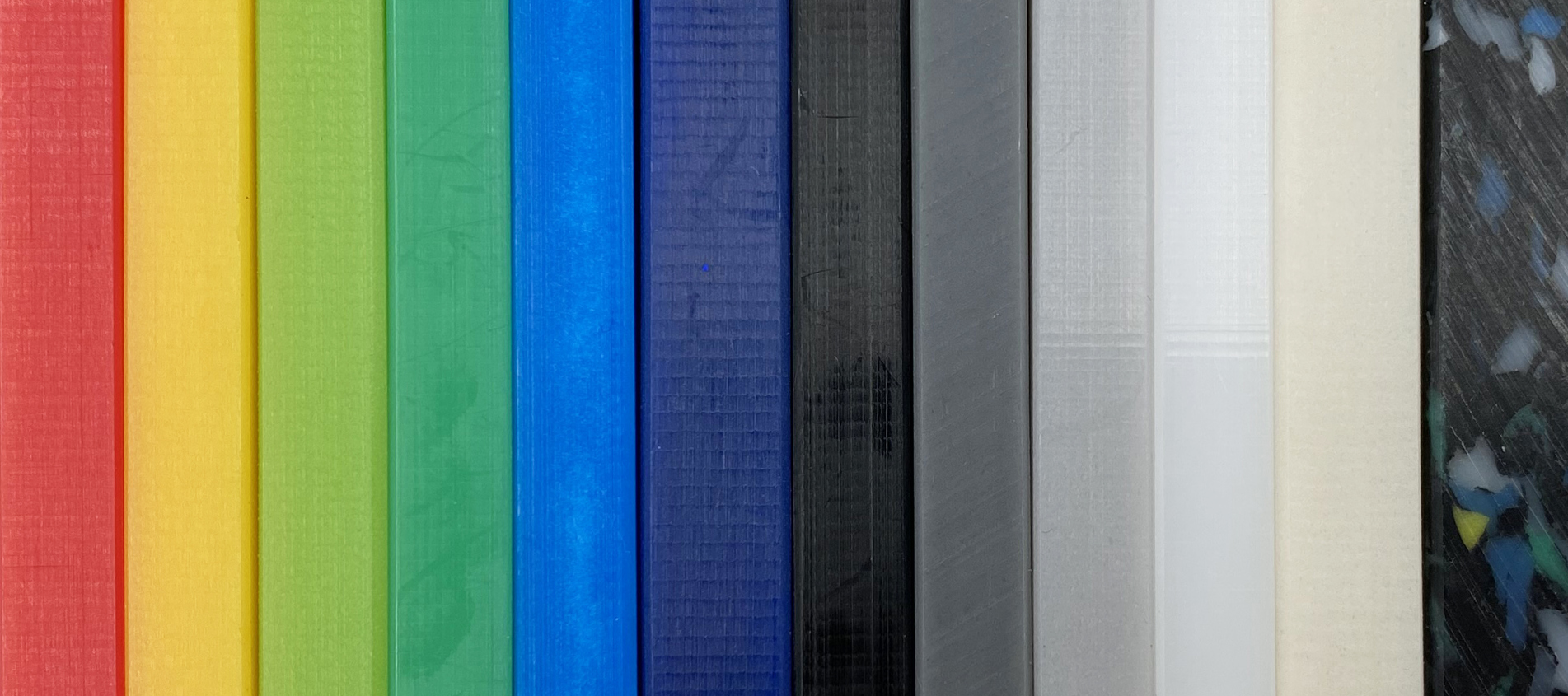

To meet the stringent requirements of food authorities, it was crucial to choose an approved solution for use in food contact applications. QUPAQ contacted Induflex to find a plastic type tailored to their needs.

"In addition to being a food-grade plastic, POM (Polyoxymethylene) has high wear resistance and low friction, making it suitable for dispensing systems that are constantly in motion. Additionally, POM components are resistant to many chemicals essential in food production, where cleaning agents and disinfectants are often used. Therefore, POM was the right choice for this task at QUPAQ," explains Daniel Barrett, Technical Specialist at Induflex.

High Functionality and Ergonomic Benefits

By implementing dispensing screws in white POM-C, side panels, parallel arms, and end pieces in black POM-C, QUPAQ has gained several benefits from using POM in their production.

"The choice of engineering plastic for our tray dispensers was to achieve several ergonomic benefits, such as ease of assembly for our customers. It not only facilitates the assembly process but also aids in the cleaning process for our customers. This was achieved without compromising the high functionality of our machine design," explains Søren B. Skjærbæk, Planning & Purchasing Manager at QUPAQ.

Flexibility – A Shared Value

Over the past decade, Induflex has produced and supplied machine parts in food-grade plastic for QUPAQ's machines. According to QUPAQ, easy collaboration and flexible production have been crucial for the many years of partnership.

"We also design and produce customized solutions. Therefore, we need subcontractors who can do the same. Induflex has demonstrated this on several occasions, where we have needed both larger and very small series. They have always provided excellent service and have friendly employees who are easy to work with. Therefore, we will continue the partnership in the future," explains Søren B. Skjærbæk.

All parts are precision machined using CNC turning and CNC milling according to QUPAQ's design and produced in food contact material (FCM) with full traceability.

For more information on traceability and food contact materials, you can read more here.

Watch the video below to gain more insight into the production of the dispensing screws.

Cases