Questions and answers

-

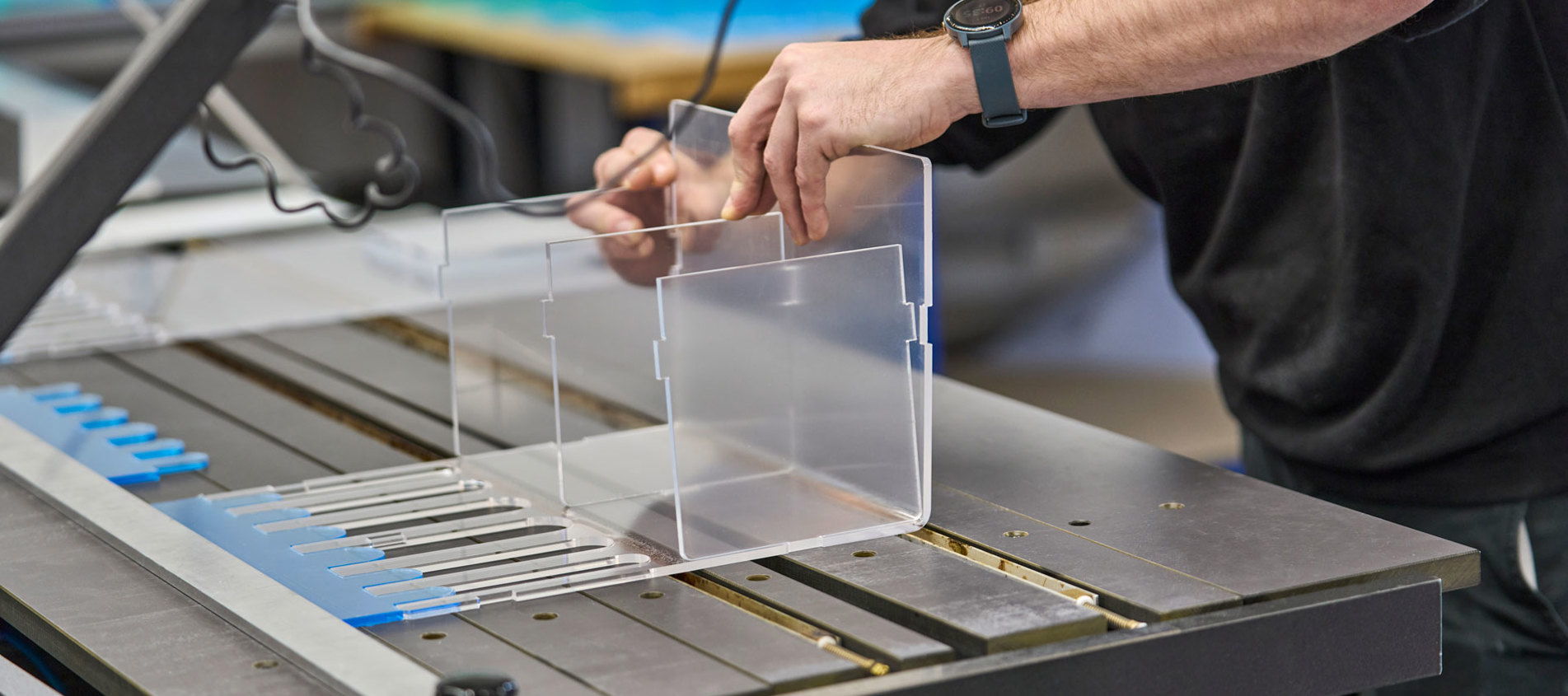

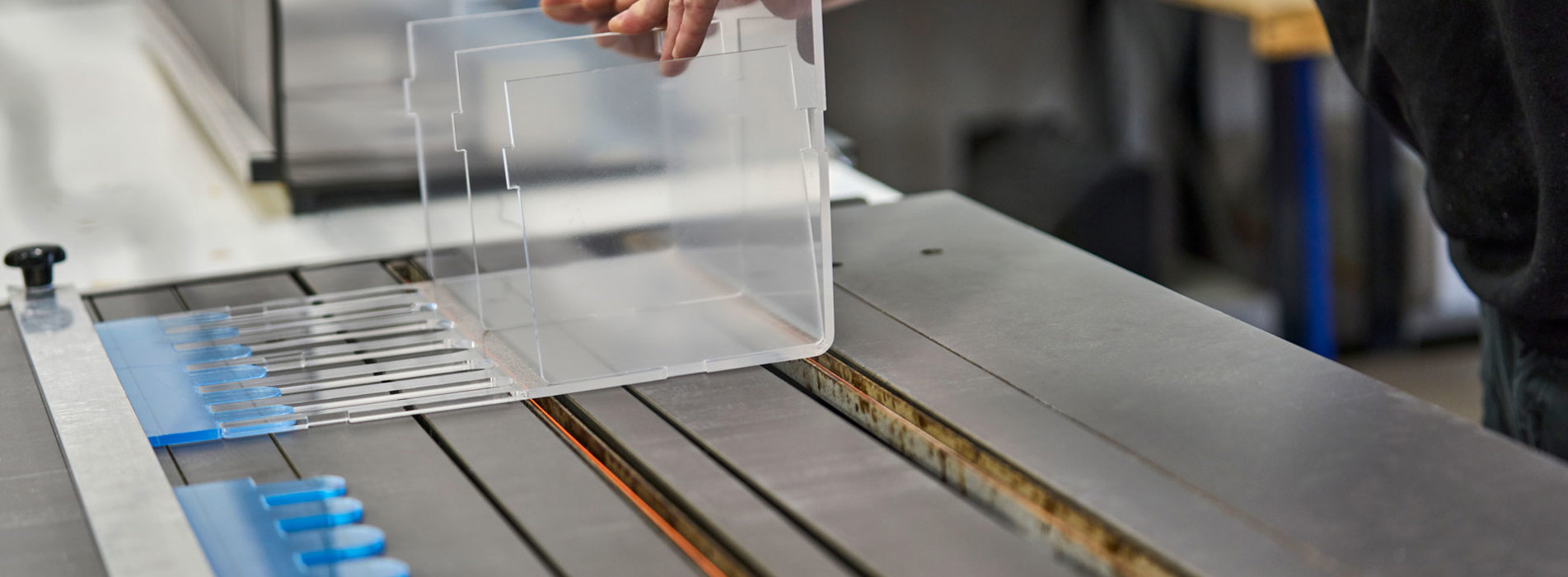

We can perform hot bending on your components in the following plastics:

- Acrylic (PMMA)

- Polycarbonate

- PETG

- ABS

- HDPE 300

- Polypropylene (PP)

If you have any questions regarding the production of your component, feel free to contact us.

-

Depending on the geometry and size of the item, we can generally hot bend your materials in the following thicknesses:

- Acrylic (PMMA) up to 6 mm thickness

- Polycarbonate up to 10 mm thickness

- PETG up to 10 mm thickness

- ABS up to 10 mm thickness

- PEHD 300 up to 10 mm thickness

- Polypropylene (PP) up to 6 mm thickness

If you have any questions about the production of your item, please feel free to contact us.

-

If you would like to receive a non-binding quote or place an order, simply send an email to induflex@induflex.dk.

Please attach a drawing of your item in STEP format, along with a PDF if possible.

You are also welcome to call us at +45 9837 1988 or fill out the contact form below, and we will ensure that the right employee contacts you.

We will send you a quote with a price before we start producing your order, unless we agree otherwise.

-

At Induflex, we can produce even very tight tolerances in plastic.

When you order a plastic component from us, it will meet the Danish Standard ISO 2768-1 (medium) as standard. We measure tolerances at room temperature, around 21 °C.

Of course, we can agree on a different tolerance if you wish.

Have any questions?

Bárður Jónsson Stórá

Sales Coordinator