Have any questions?

Daniel Dam Barrett

Technical Advisor & Sales

Bárður Jónsson Stórá

Sales Coordinator

Questions and answers

-

There may be mechanical requirements that plastic cannot meet.

Plastic is typically not suitable for constructing long elements, such as beams, that are several meters long and subjected to constant pressure. In such a construction, the plastic will simply bend.

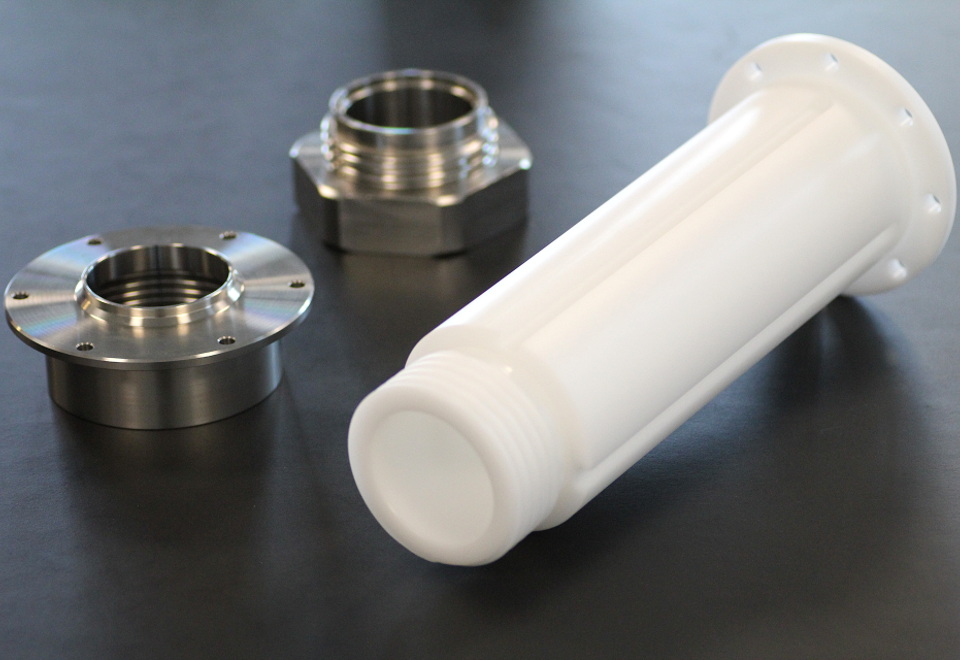

However, if there are no mechanical requirements of that nature, plastic can be a good alternative for machine parts. Plastic is ideal for many machine components, frames, spacers, and much more.

-

If you are switching from metal—or another material—to plastic, you should be aware that the metal design may not necessarily translate directly to the new plastic construction.

This means that the component needs to be reconstructed to avoid defects in strength or surface quality.

When reconstructing, considerations should be made regarding the purpose and the environment in which the component will be used, such as:

- Strength

- Stiffness

- Coefficient of expansion

- Temperature resistance

- Tolerances

- Regulations

Most importantly, it is essential to identify and communicate the usage to Induflex, as this information and the details can be crucial for selecting the right material. Only through shared insights can we achieve the perfect solution for your project.

-

Many machine parts can be converted to plastic. We have extensive experience in converting various machine components such as gears, screws, subcomponents, and profiles.

Whether it's metal, steel, or wood, your item might be eligible for reconstruction.

-

Do you want to know if your machine part(s) can be converted to plastic? And what savings and benefits you could achieve?

Send a drawing of your machine part(s) in either DXF or STEP format, along with a PDF, to induflex@induflex.dk, and we will get back to you.

You are also welcome to call us at +45 9837 1988 or fill out the contact form below— we will ensure that the right specialist contacts you.

-

At Induflex, we can produce even very tight tolerances in plastic.

When you order a plastic component from us, it will meet the Danish Standard ISO 2768-1 (medium) as standard. We measure tolerances at room temperature, around 21 °C.

Of course, we can agree on a different tolerance if you wish.