The Industry's

Plastic Partner

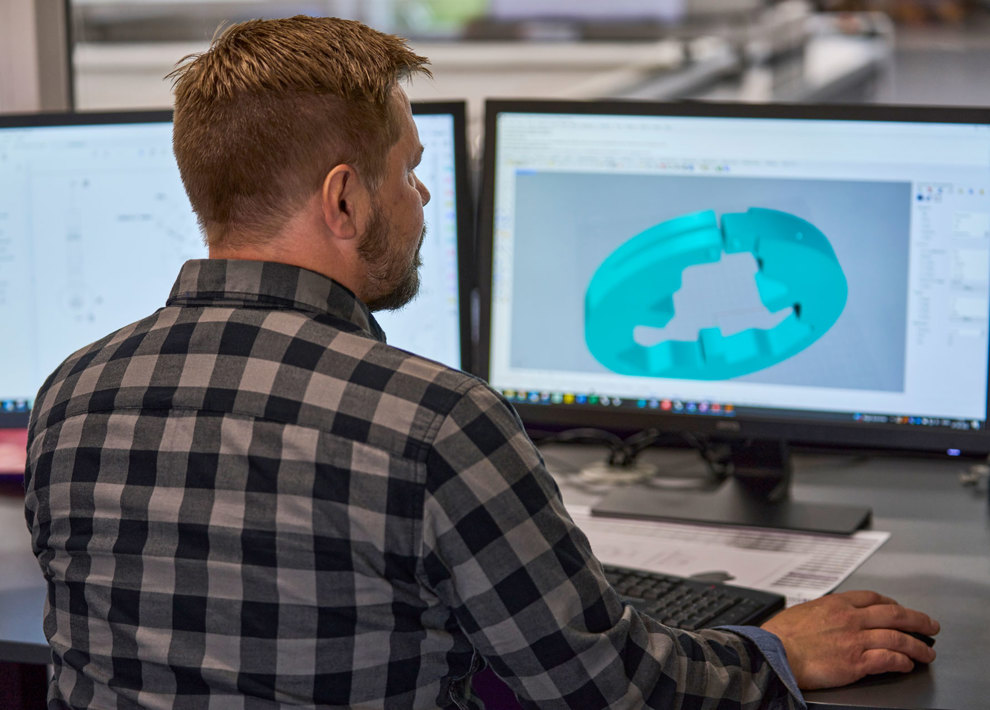

At Induflex, we believe in creating valuable solutions for our customers through technical plastics. As "The Plastics Partner for Industry," we are with you every step of the way – from initial consultations on your projects to the delivery of your finished machine components.

Have any questions?

We are always ready to help you find the right solution for your project, regardless of the size of the task. Contact us today to receive a non-binding quote for your request within 24 hours.

Bárður Jónsson Stórá

Sales Coordinator

Daniel Dam Barrett

Technical Advisor & Sales

Tina Heslop Christensen

Sales and Project Coordinator