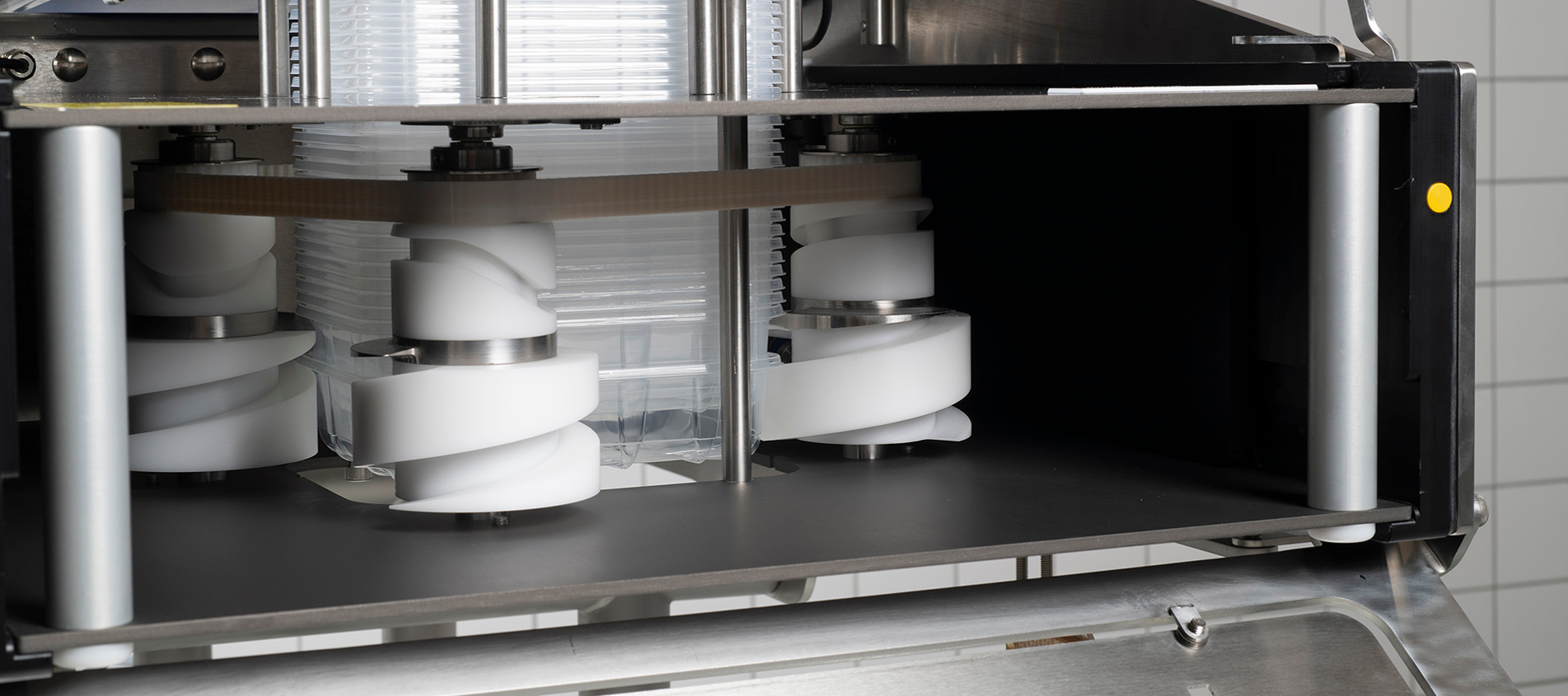

Plastic machine parts

for the Food Industry and Food Processing Industry

At Induflex, we assist a wide range of companies in the food industry. This is mainly due to the fact that the majority of our plastic types are food-approved contact materials (FCM), as well as our extensive experience in producing custom components for the food and food processing industries.

As a result, the items we produce vary greatly. This includes products such as snails, gears, gaskets, wear parts, profiles, guards, and much more.

FAQ

-

Almost all of our plastic types are standard-approved for food contact materials.

However, ABS is not approved for use in food production.

-

The short and long answer is no.

Our plastic materials are standard FCM-approved, and therefore it does not affect the price.

-

At Induflex, we can achieve very tight tolerances in plastic.

When you order a plastic component from us, it adheres to the Danish Standard ISO 2768-1 (medium) by default. We measure tolerances at room temperature, around 21°C.

Of course, we can agree on different tolerances if you prefer.

Have any questions?

Bárður Jónsson Stórá

Sales Coordinator