Have any questions?

Bárður Jónsson Stórá

Sales Coordinator

FAQ's

-

-

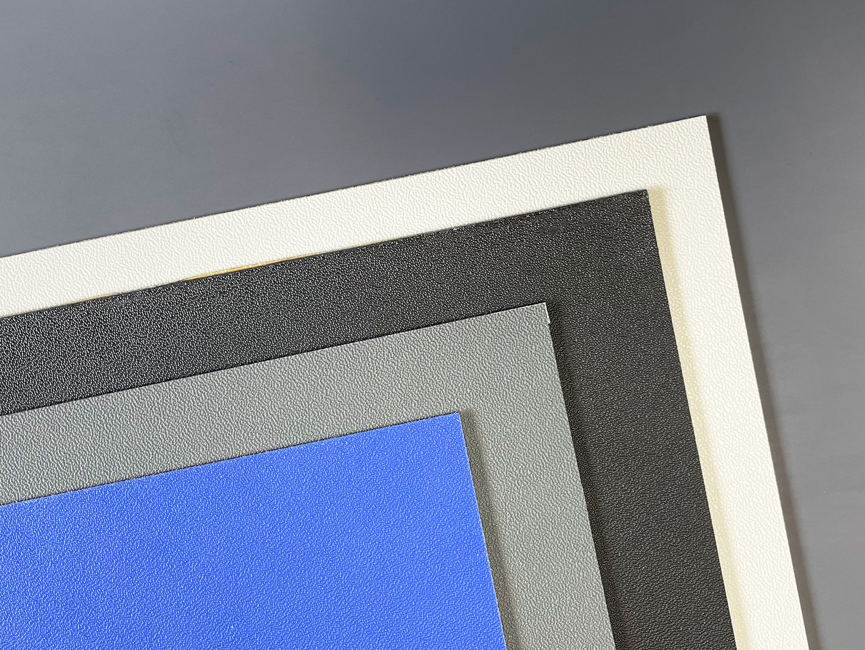

ABS is available in both sheets and rods with various surface textures (grain) and multiple colors such as blue, red, green, and yellow.

At Induflex, we can produce your ABS products in different colors and thicknesses.

As a standard, we have sheets in stock in 1.5 mm thickness, 1250 x 2500 mm in gray, blue, and white, as well as 3 mm, 1300 x 2800 mm in black. We are happy to order other colors and sizes for you.

-

At Induflex, we can achieve even very tight tolerances in plastic.

When you order a plastic part from us, it adheres to the Danish Standard ISO 2768-1 (medium) by default. We measure the tolerances at room temperature, around 21 °C.

Of course, we can agree on different tolerances if you wish.

-

By sending us a STEP file or PDF with your drawings, we can quickly help determine if PET is the right choice for your project.

We can also identify the most suitable processing method for your components.