Daniel Dam Barrett

Sales coordinator

Bárður Jónsson Stórá

Sales Coordinator

-

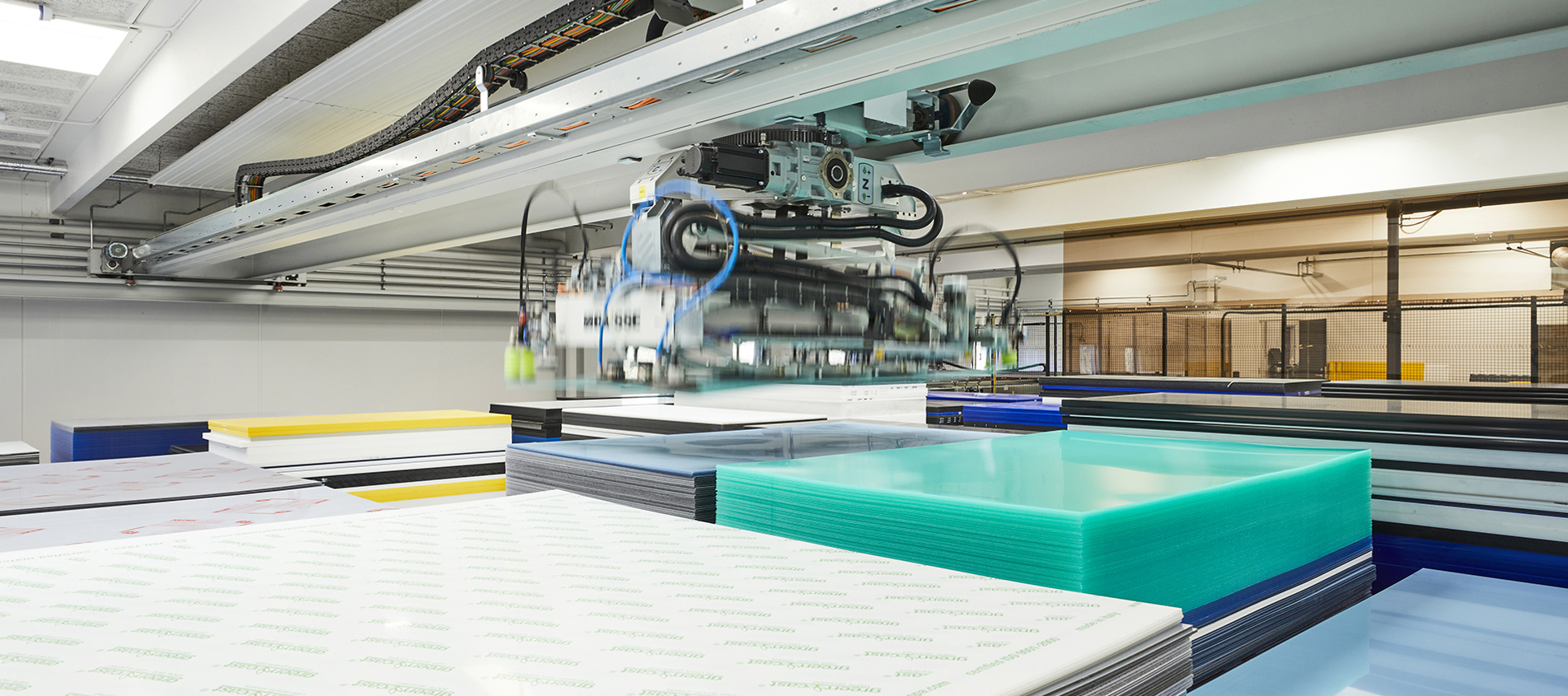

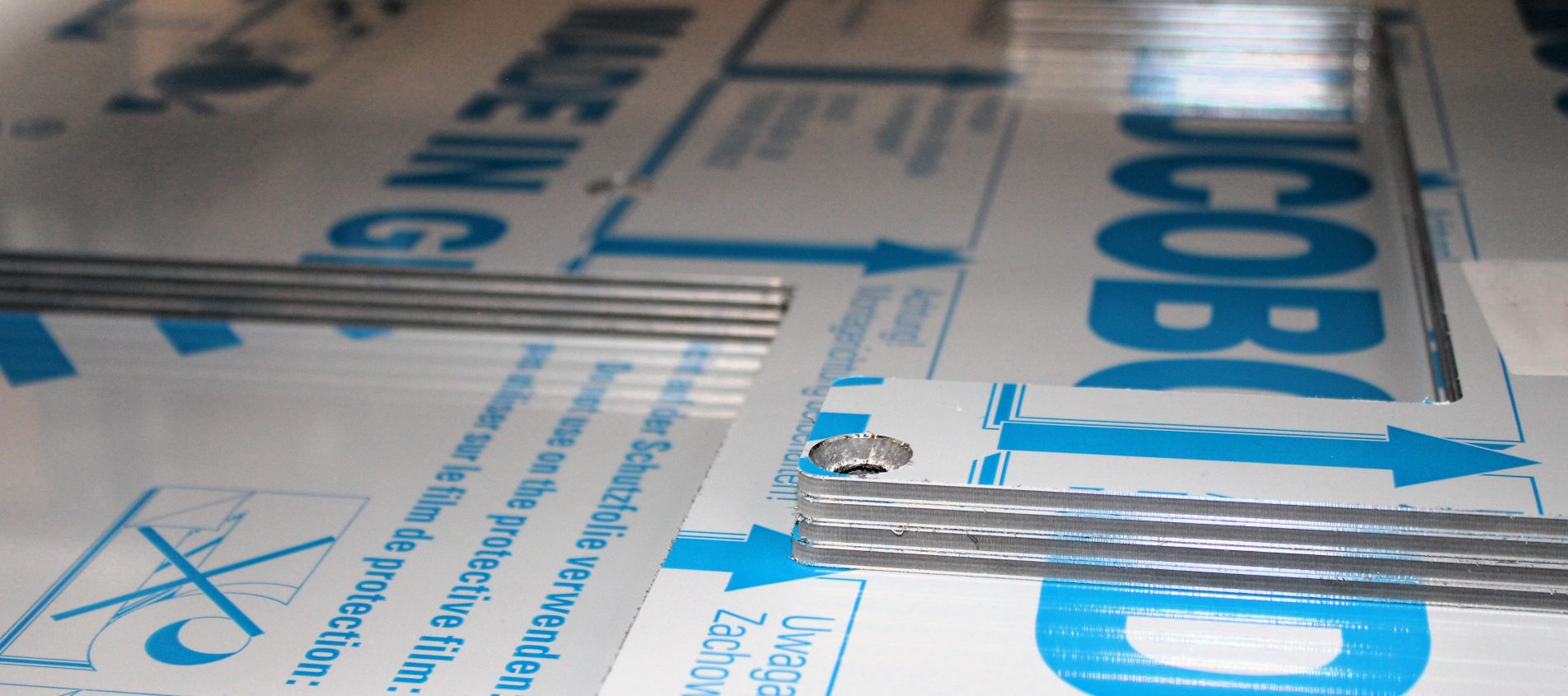

We have a large inventory of plastic and aluminum sandwich panels, allowing us to fulfill requests for standard materials within 8-14 working days, depending on the complexity of your components.

We only work with European suppliers, enabling us to quickly order materials tailored to your needs.

-

By sending us a STEP file or PDF with your drawings, we can quickly help determine if aluminum sandwich panels are the right choice for your project.

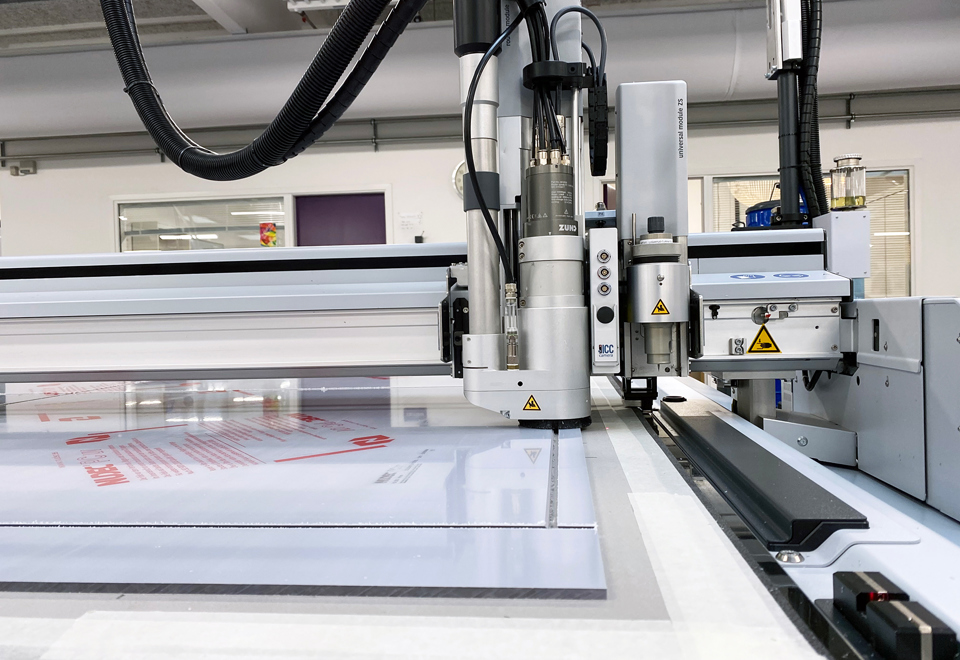

We can also identify which machining method is best suited for your components.

-

At Induflex, we can achieve even very tight tolerances in plastic.

When you order a plastic part from us, it adheres to the Danish Standard ISO 2768-1 (medium) by default. We measure the tolerances at room temperature, around 21 °C.

Of course, we can agree on different tolerances if you wish.