Have any questions?

Daniel Dam Barrett

Technical Advisor & Sales

Tina Heslop Christensen

Sales and Project Coordinator

Spørgsmål og svar

-

-

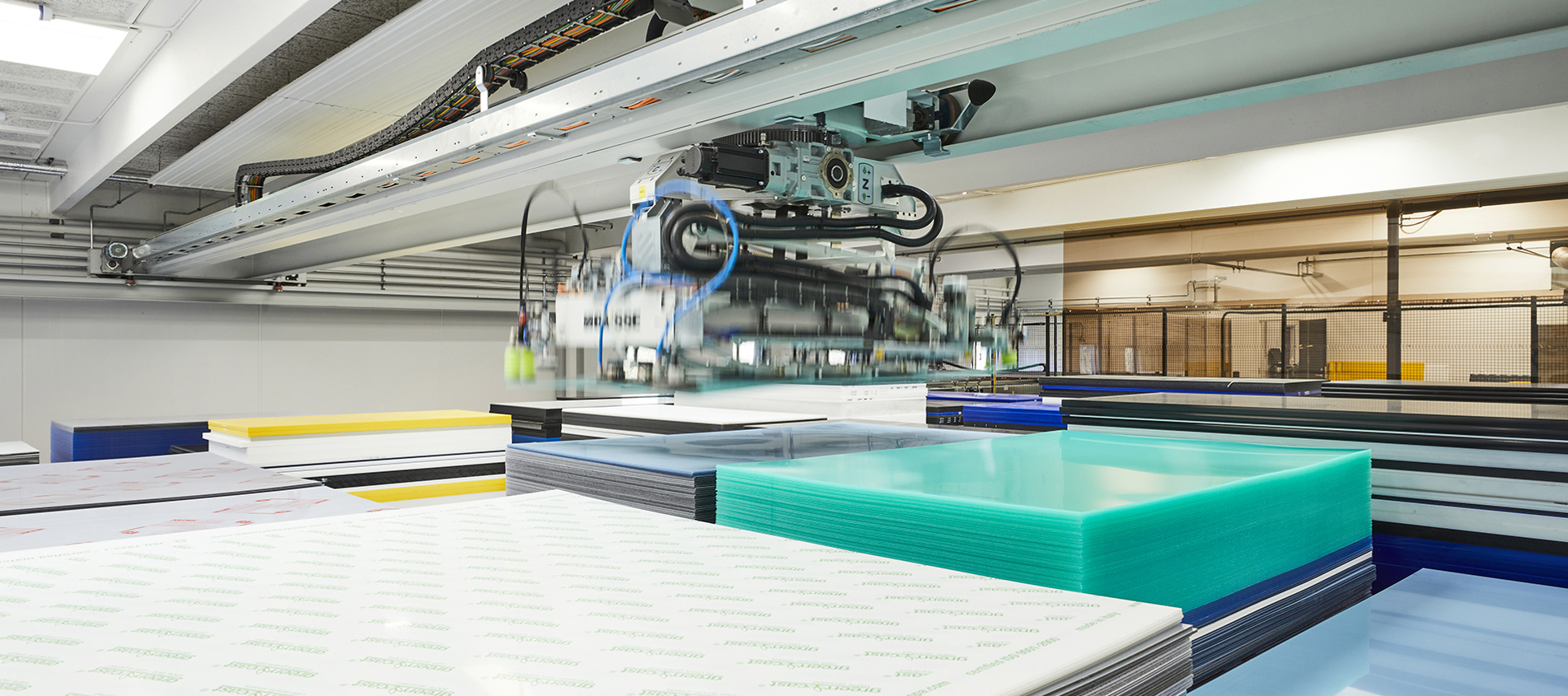

At Induflex, we can achieve even very tight tolerances in plastic.

When you order a plastic part from us, it adheres to the Danish Standard ISO 2768-1 (medium) by default. We measure the tolerances at room temperature, around 21 °C.

Of course, we can agree on different tolerances if you wish.

-

Like many other thermoplastics, PET is notch-sensitive. Therefore, constructions should be designed without sharp internal corners.

If a design combines notch effects with internal stresses, it doesn't take much for the PET to crack during processing, transportation, or initial use.

Additionally, it is also hydrolysis-sensitive.

-

By sending us a STEP file or PDF with your drawings, we can quickly help determine if PET is the right choice for your project.

We can also identify the most suitable processing method for your components.