Have any questions?

Daniel Dam Barrett

Technical Advisor & Sales

Bárður Jónsson Stórá

Sales Coordinator

FAQ

-

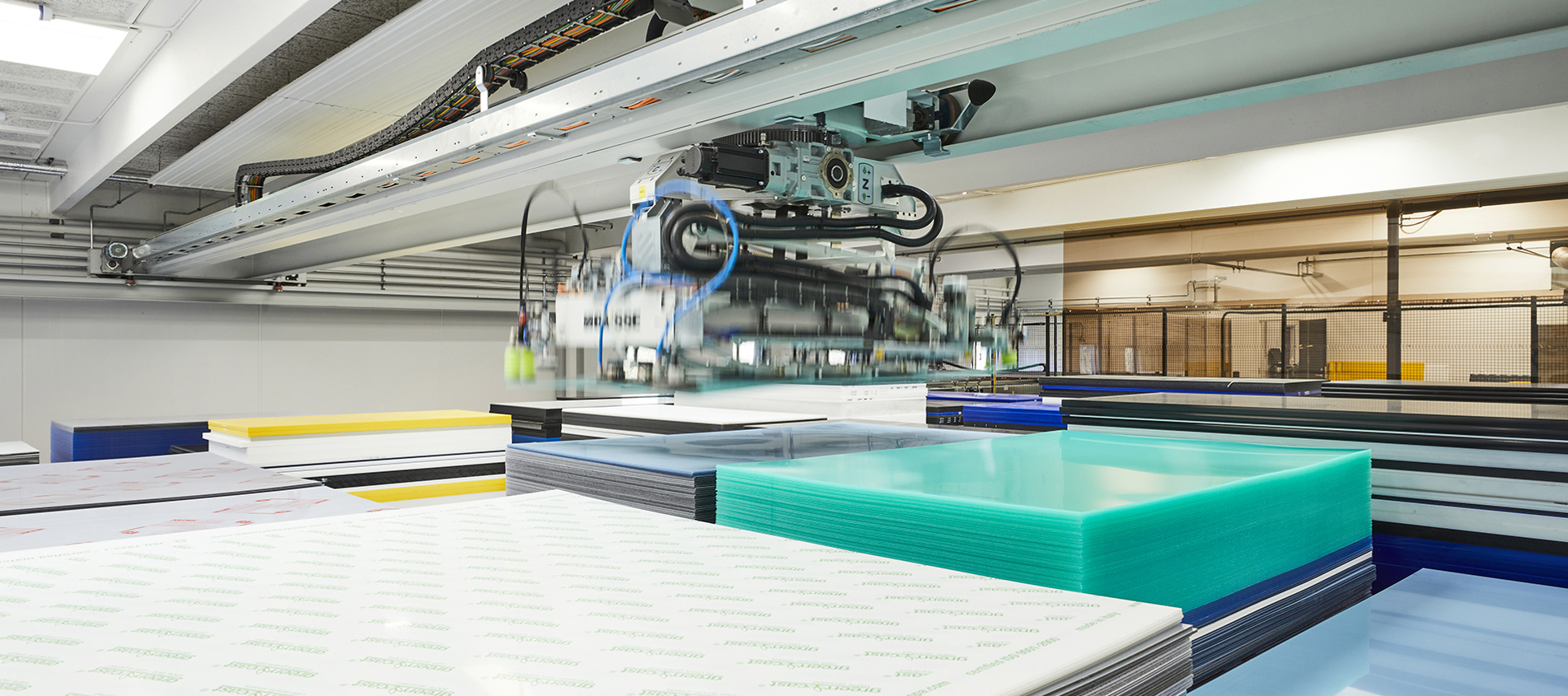

We maintain a large stock of plastic materials, allowing us to meet requests for standard material items within 8-14 working days, depending on the complexity of your component.

If your project requires more specialized plastics, such as POM in custom colors, we typically operate within a month.

We work exclusively with European suppliers, ensuring that we can quickly order materials to meet your needs.

-

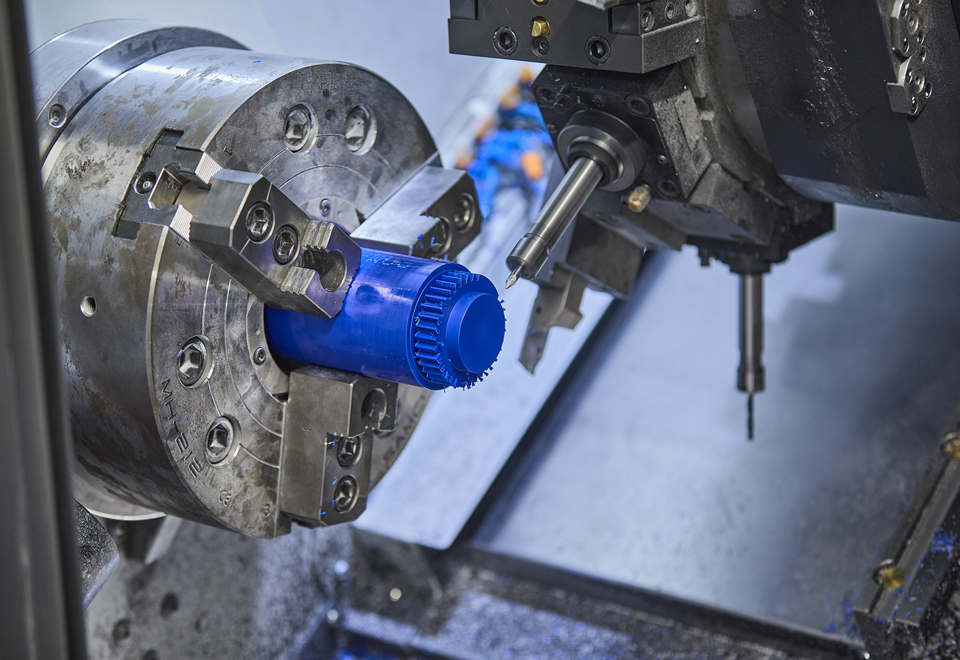

POM is available in both sheets and round rods in a wide range of sizes.

At Induflex, we utilize rods ranging from Ø3 to Ø300, with lengths of 1 or 3 meters, as well as sheets from 1 mm to 300 mm in thickness, with widths of 1220/1000/620/500 mm and lengths of 1000/2000/3000 mm.

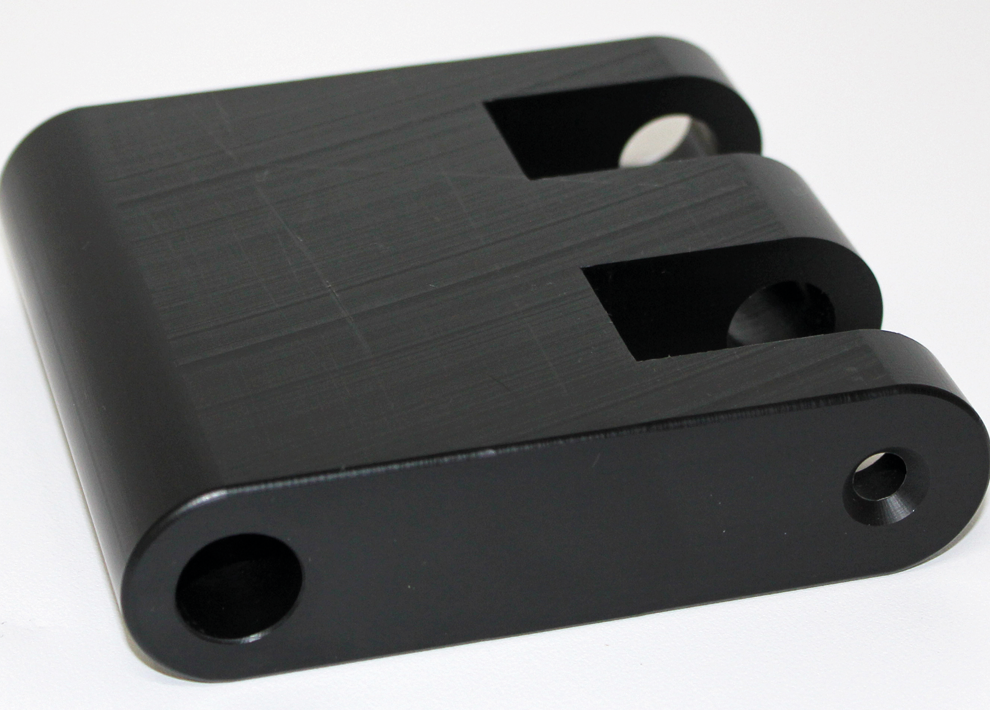

This provides ample opportunity to create components in various sizes from POM.

We offer standard colors including natural/white, black, and blue.

-

At Induflex, we can achieve even very tight tolerances in plastic.

When you order a plastic part from us, it will, as standard, comply with Danish Standard ISO 2768-1 (medium). We measure the tolerances at room temperature, around 21 °C.

Of course, we can agree on different tolerances if you prefer.

-

POM-C stands for POM Copolymer, while POM-H stands for POM Homopolymer.

There are differences between POM-C and POM-H, for example, regarding chemical resistance.

When referring to POM in general, it is usually POM-C that is meant.

POM-C is indeed the most commonly used POM and is also the standard at Induflex.

-

POM is an FCM-approved technical plastic, which means it can be used for components that come into direct contact with food, such as machine parts in food production equipment.

As a result, POM is widely used in the food and beverage industry.

-

By sending us a STEP file or PDF with your drawings, we can quickly assist in determining whether POM is the right choice for your project.

We can also identify which machining method is best suited for your item.