Har du spørgsmål?

At Induflex, we are specialists in plastics. We are ready to help you identify your needs so you can choose the right material for your project. Contact us today for personalized advice on your project.

Daniel Dam Barrett

Technical Advisor & Sales

Bárður Jónsson Stórá

Sales Coordinator

Spørgsmål og svar

-

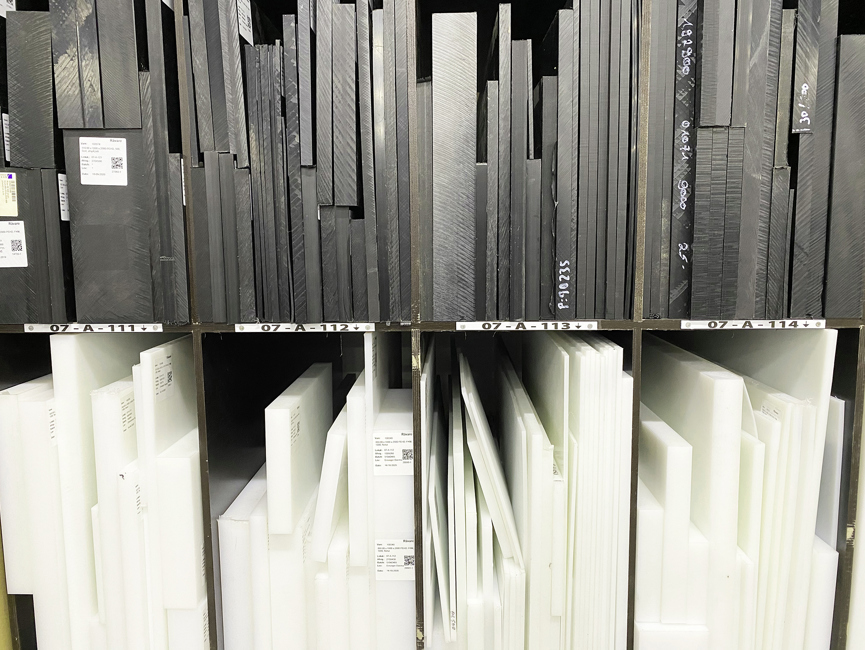

We have a large inventory of plastics, allowing us to meet requests for standard materials within 14 working days, depending on the complexity of your components.

If your project requires more specialized plastics, such as PVDF with additives, we operate within one month.

We only collaborate with European suppliers, enabling us to quickly order materials to meet your needs.

-

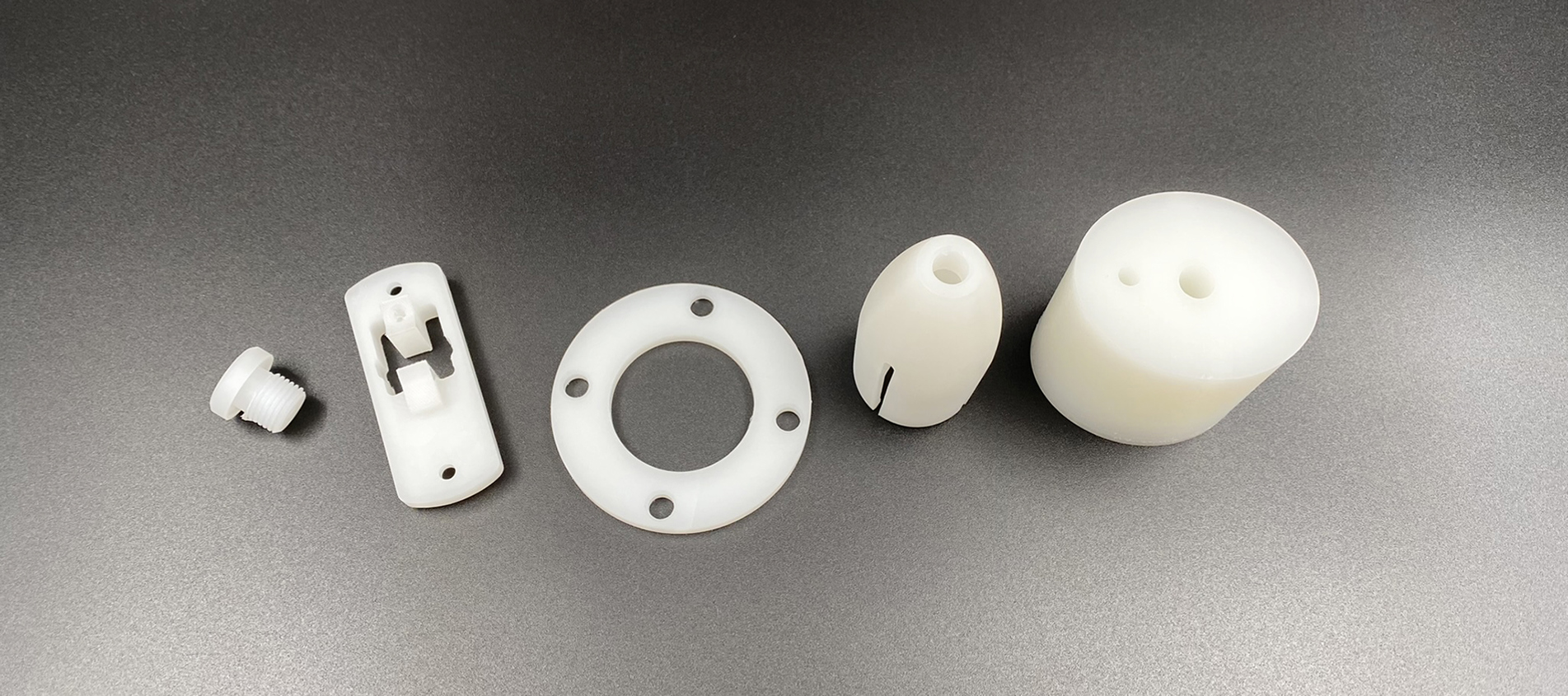

At Induflex, we can produce even very tight tolerances in plastic.

When you order a plastic part from us, it will meet Danish Standard ISO 2768-1 (medium) as standard. We measure the tolerances at room temperature, around 21 °C.

Of course, we can agree on different tolerances if you wish.

-

Our competencies

With over 35 years of experience in plastic processing, Induflex is the flexible and specialized partner for custom plastic solutions in the industry.

Our standards

To ensure quality, safety, and compatibility, we at Induflex work according to professional protocols and use materials that comply with recognized standards.