Plastics for the food and beverage industries

Machine parts in plastic for the food industry and the food processing industry

It is hard to imagine producing and selling food without the use of plastics. Plastic is used to produce the mechanical components, wear parts and screens used in and around the food industry's production equipment.

Machine parts such as swing arms, dispensers, knuckle pulleys, scale pans, toothed wheel – all produced in plastics.

We have significant capacity and knowledge of processing plastic parts and machine parts for use in food processing machines and production facilities.

Production of machine parts in food-approved plastics

We manufacture machine parts in plastic for machinery and plant that processes both frozen and fresh foods. Our plastic parts are manufactured in food-approved material.

All plastics produced for the food and beverage industries are customer-specific and are made according to your requirements and specifications – irrespective of whether you need one, or several thousand items.

Advantages of using plastics in the food industry

Plastic is increasingly indispensable in the food and beverage industries, and not without reason.

The advantages of plastic compared with steel and aluminium are such qualities as:

- 100 % food-approved material

- Low bulk density

- Low friction

- Self-lubricating properties

- Short production processes.

Find a supplier with the right approvals

All plastic that comes into direct contact with food must be food-approved and traceable.

Since 2011, Induflex has been approved as a supplier of plastics for plastic components destined for the food and beverage industries. If we act as your supplier and processor of raw materials, you can rest assured that the relevant documentation and approvals will be in place.

Read more about the Danish Smiley Scheme here.

You can find our latest control reports from the Food Administration here.

Traceability with just one click

Food-approved plastics from Induflex are traceable not only to the appropriate raw material manufacturer; our system, which uses QR tracing codes allows for the material to be traced back to the individual raw material sheet or rod and the batch from which it came.

CNC-processing methods for food-approved plastic

CNC milling and turning are generally considered to be processes that have no impact on the plastic's effect on foods. Plastics made from food-approved plastic sheets and rods using CNC processing can therefore be used in contact with food without the need for a separate certificate.

Clean production facilities and clean plastic parts

Since we process plastics as a run-of-the-mill activity, we do not need lubricating agents. Cooling is by air alone. This means our production and your blanks are clean when you receive them.

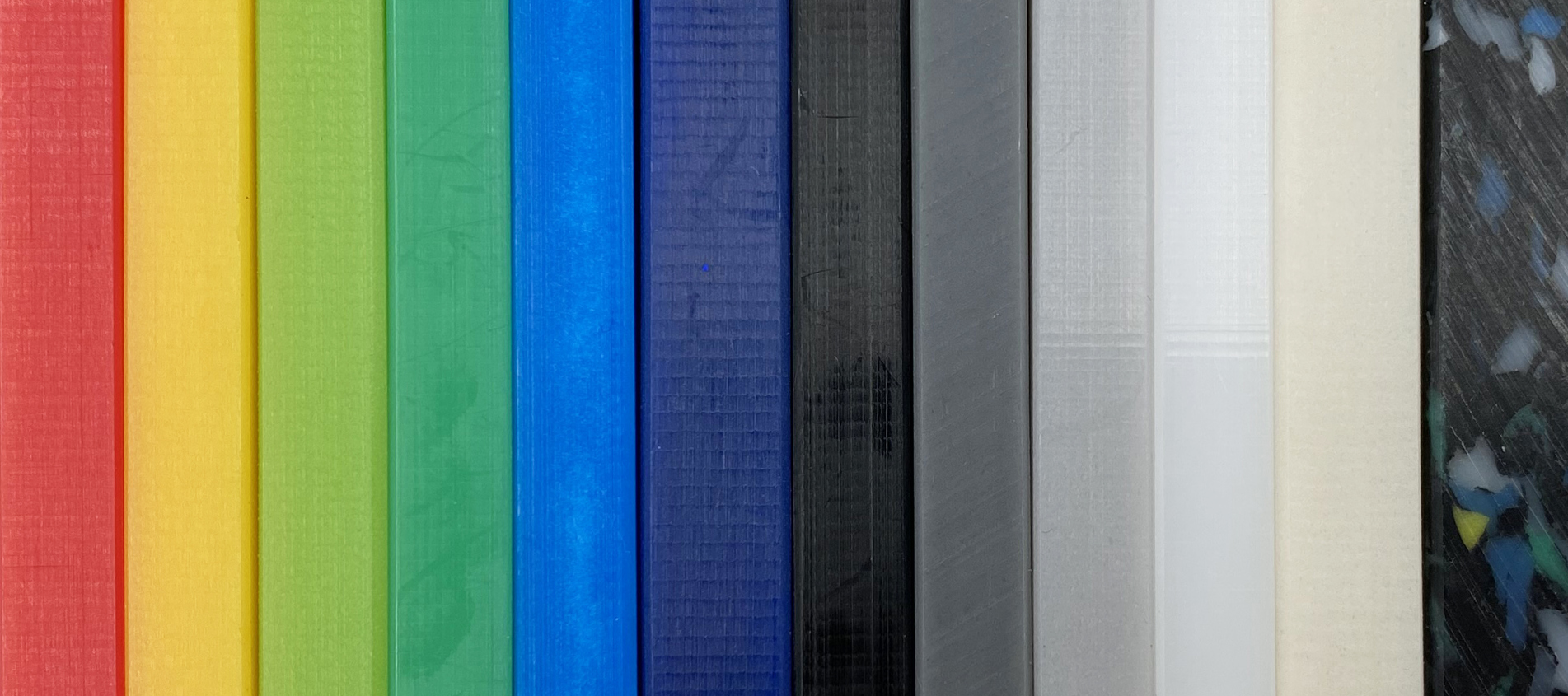

Materials for the food and beverage industries

The various types of plastic afford their particular advantages with respect to the food industry and food production.

- PEHD500 / PEHD1000 are fantastic with respect to wear when water or sand are used. Perhaps these are the most widespread plastics to be used in the food sector, not least due to their excellent properties.

- Polyamide (nylon) is a tough material that can withstand extreme loads and pressure.

- POM has a short process time to production and can cope with high loads.

- PTFE (Teflon®) is a relatively soft plastic with extreme friction.

- PEEK has good mechanical properties and a good thermal stability. It can handle high temperatures up to 250 ⁰C

- PVDF is especially fit for hygienic environments like the healthcare or the dairy industry

The choice of plastic when making machine parts for food processing is not a random one. It is important to choose the right plastic for the task at hand. Take advantage of our experience and the advice we can give you. We have materials to suit most jobs.

Our materials fulfil technical requirements such as:

- Traceability, either visual or with a metal detector

- Salt water and sand

- Cleaning with chemicals or steam

- Vegetable oils

- High and low temperatures

Case